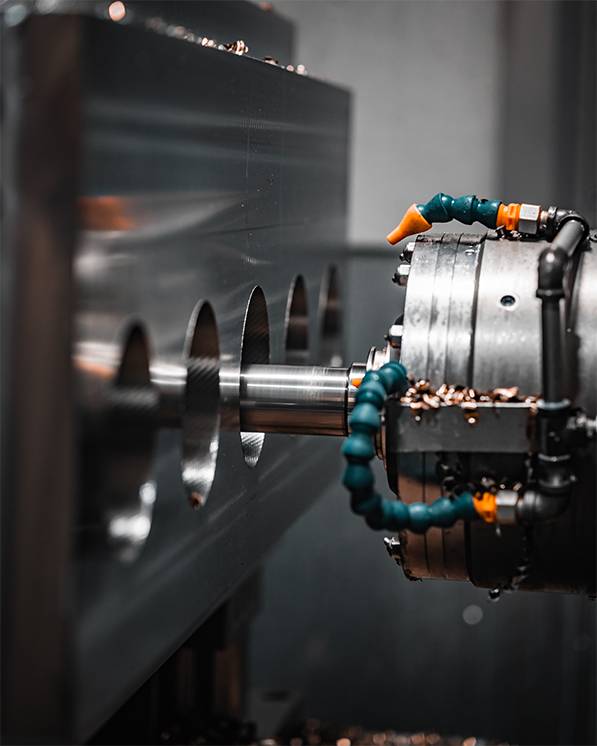

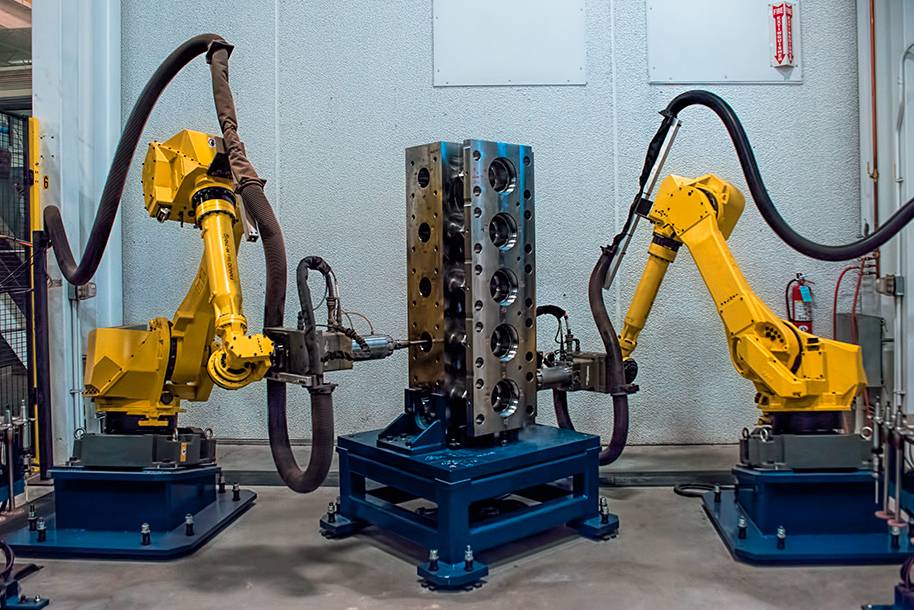

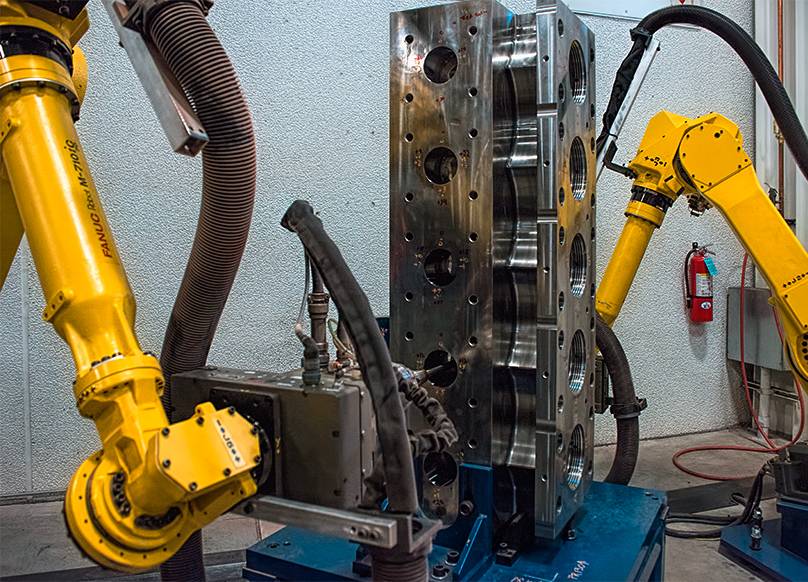

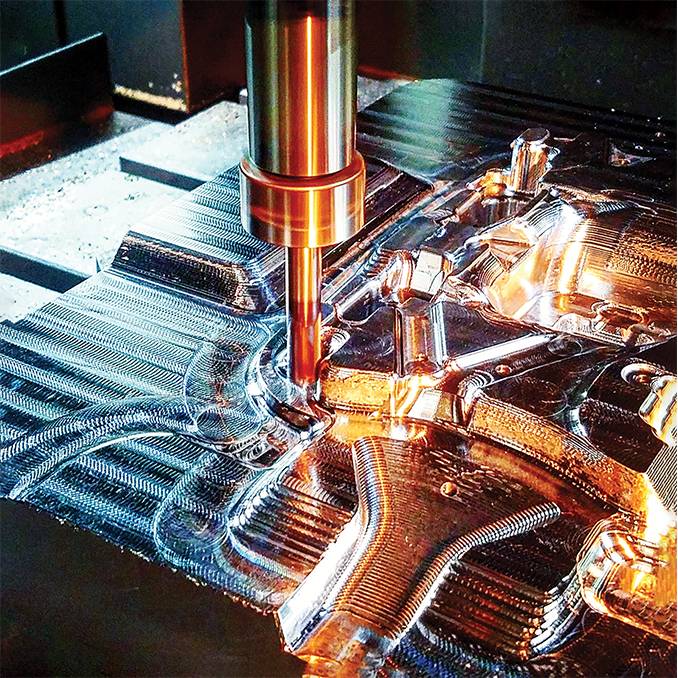

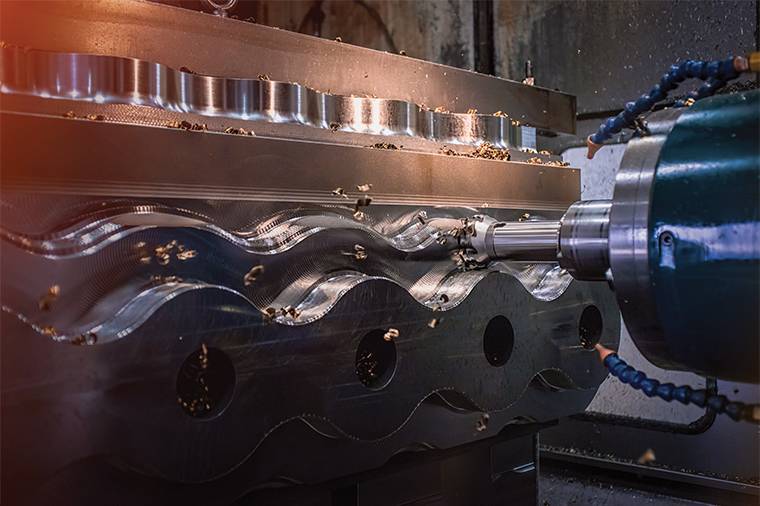

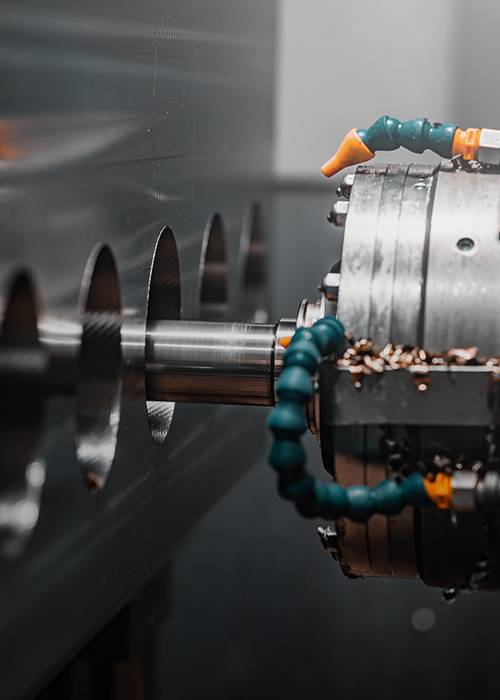

CNC Manufacturing Services

RAM Tool provides CNC manufacturing services with full in-house control from design to delivery. Our advanced machining facility includes a wide range of equipment for milling, grinding and drilling. By keeping projects in-house, we maintain control over accuracy, scheduling and quality, while also reducing costs and lead times. Our capacity encompasses large weldments and fabrications, making us ideal for both small-run and high-volume production of CNC machining services. Contact us today to request a quote.

Get

Get