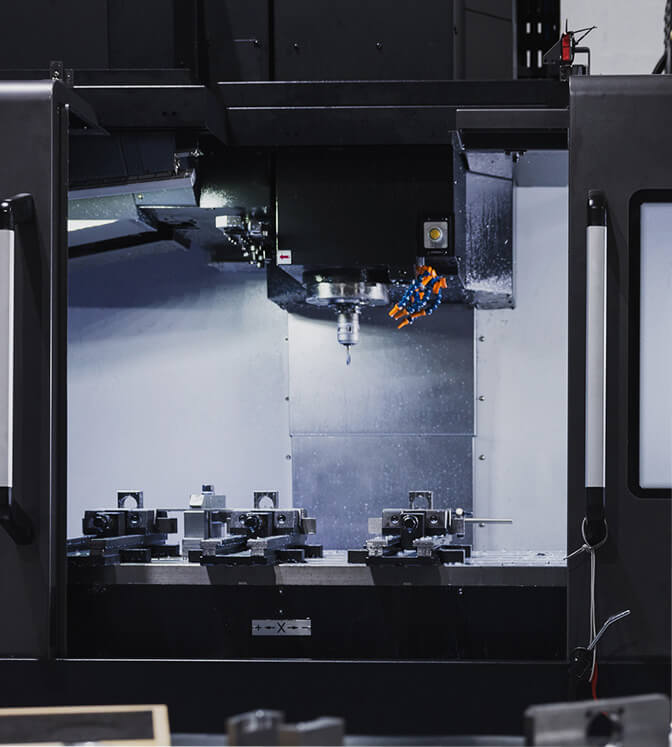

Our facility owns eight CNC Horizontal Boring Mills that we use for custom CNC services. We have eight Kuraki KBT13EA models with a 5.12" spindle diameter in five unique configurations: two Kuraki boring mills with a 51" x 98" x 157" travel capacity and 44,000-pound max pallet load, two Kuraki boring mills with a 51" x 90" x 157" travel capacity and 44,000-pound max pallet load, two Kuraki boring mills with a 51" x 90" x 118" travel capacity and 44,000-pound max pallet load, one Kuraki boring mill with a 51" x 90" x 118" travel capacity and 33,000-pound max pallet load, and one Kuraki boring mill with a 51" x 78" x 118" travel capacity and 26,400-pound max pallet load. These eight milling machines are capable of performing precision tolerances of .00508 millimeters.

Kuraki KBT-13EA (51" x 98" x 157")

This powerful Kuraki horizontal boring mill offers exceptional precision and capacity for large-scale machining projects. With a massive 44,000 lbs. table load capacity and expansive work envelope, it's ideal for heavy-duty manufacturing in industries like aerospace and energy.

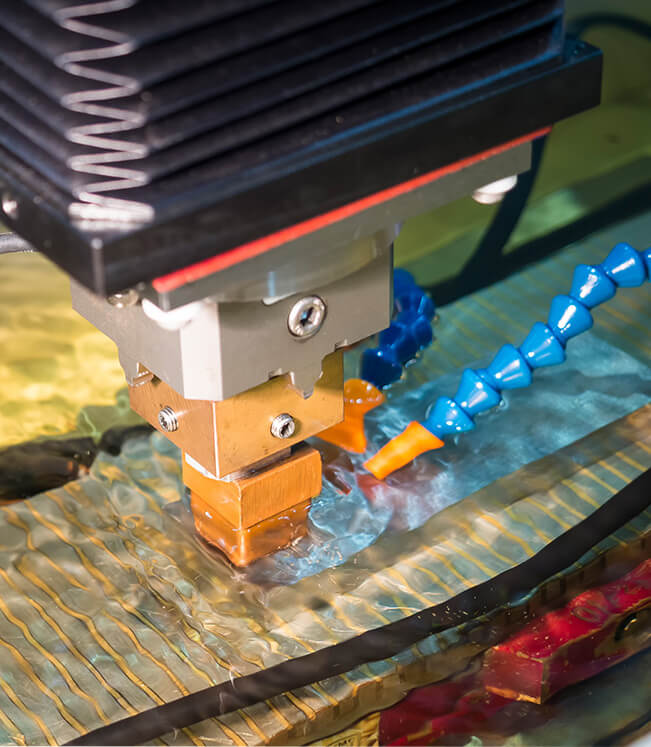

Kuraki KBT-13EA (51" x 90" x 157")

This Kuraki machine maintains an impressive 44,000 lbs. load capacity while offering a slightly reduced X-axis travel. It still provides ample workspace for complex machining operations on large workpieces.

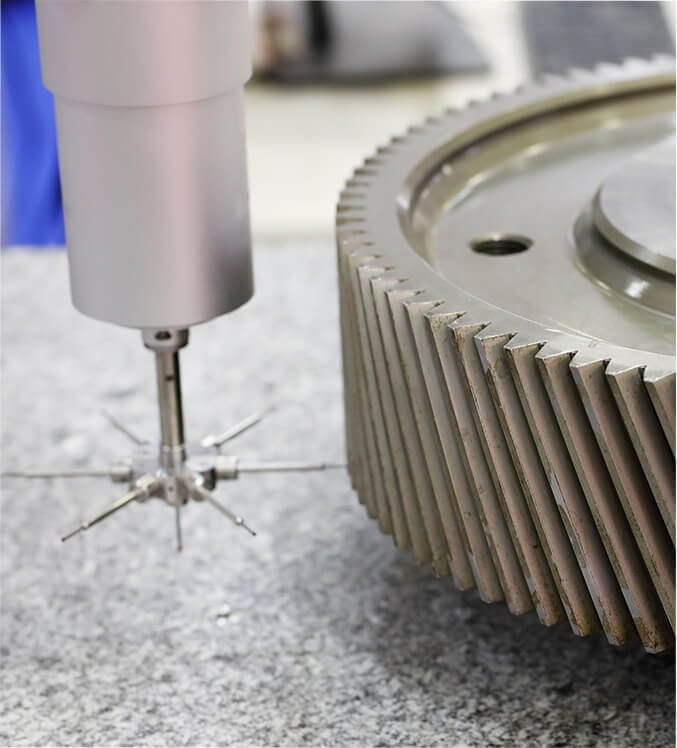

Kuraki KBT-13EA 5.12" (51" x 90" x 118")

This Kuraki KBT-13EA 5.12" CNC Table Type Horizontal Boring Mill features a load capacity of 33,000 lbs. This model is ideal for projects that require precision machining of moderately sized workpieces.

Kuraki KBT-13EA 5.12" (51" x 78" x 118")

The most compact version in the Kuraki KBT-13EA series. This model is ideal for the precision machining of smaller, lighter workpieces while still offering the reliability and accuracy that Kuraki boring mills are known for.

Get

Get