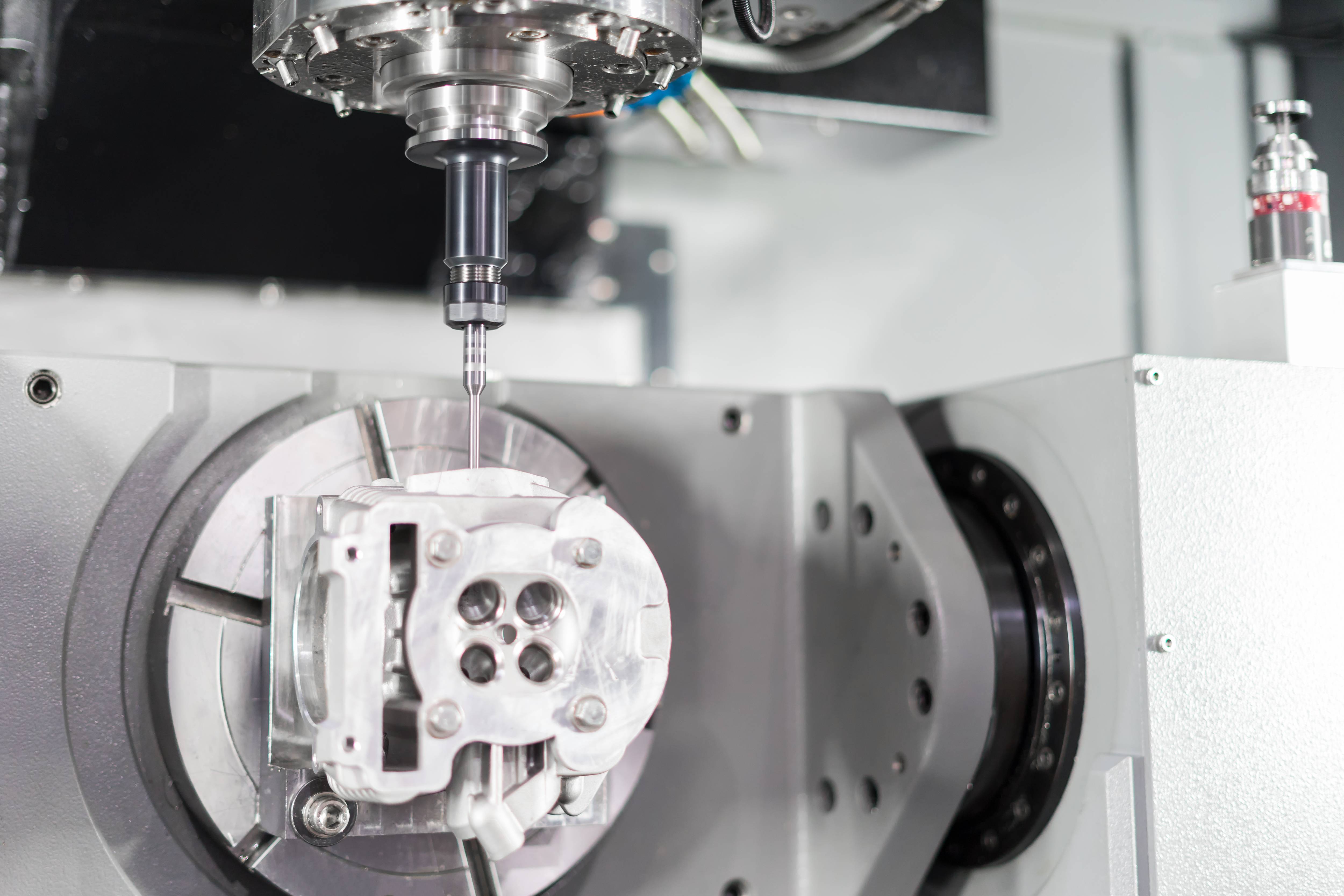

Hermle C 42 U CNC High-Speed Precision 5-Axis Machining Center

The Hermle C 42 U is a high-performance 5-axis machining center designed for precision machining of complex parts. It features a 31.5" x 24.5" working area, 18,000 RPM spindle, and can handle workpieces up to 4,409 lbs.

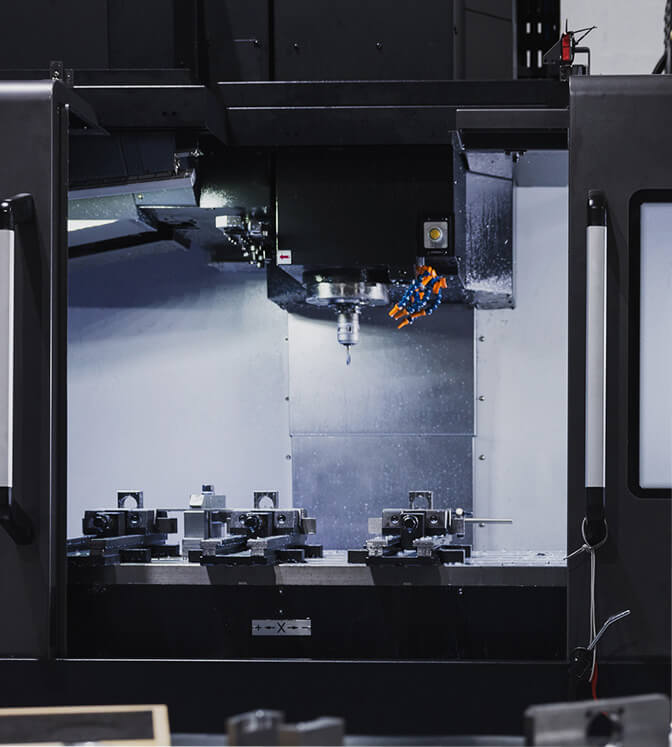

APEC G Series G2540 CNC High-Speed 5-Axis Gantry Type Machining Center

The APEC G2540 is a gantry-style 5-axis machining center built for high-speed cutting of large workpieces. It offers a 157.5" x 94.5" x 47.2" table size and rapid traverse rates of up to 60 m/

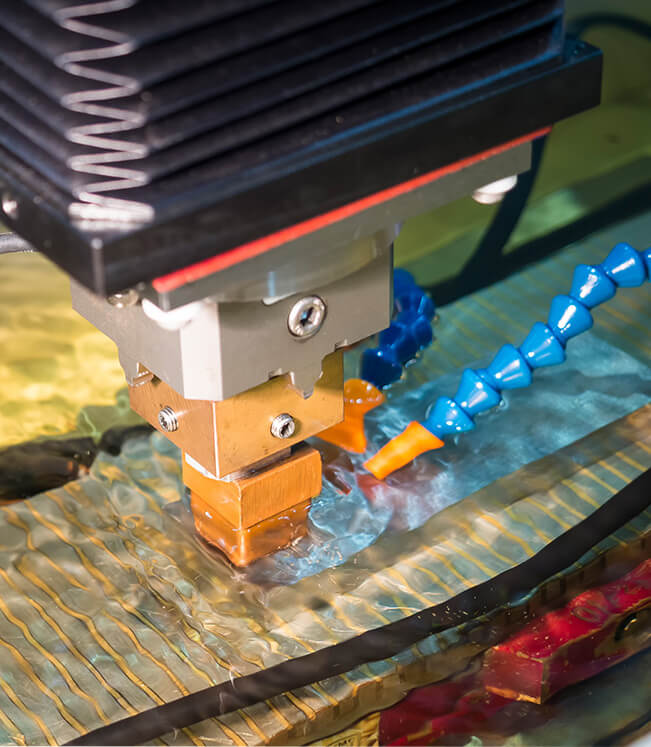

JOBS LINX 450 Compact 5-Axis Gantry Type Machining Center

The JOBS LINX 450 is a compact gantry-style 5-axis machining center designed for high-precision custom machining. It features a 157” x 118” x 59” table, 15,000 RPM spindle, and linear motors on all axes for superior accuracy and surface finish.

DMG MORI DMC 125 U duoBLOCK 5-Axis Machining Center

The DMG MORI DMC 125 U duoBLOCK is a large-capacity 5-axis machining center with a 39.4" x 31.5" pallet for heavy-duty cutting. It offers a rigid duoBLOCK design for stabilit

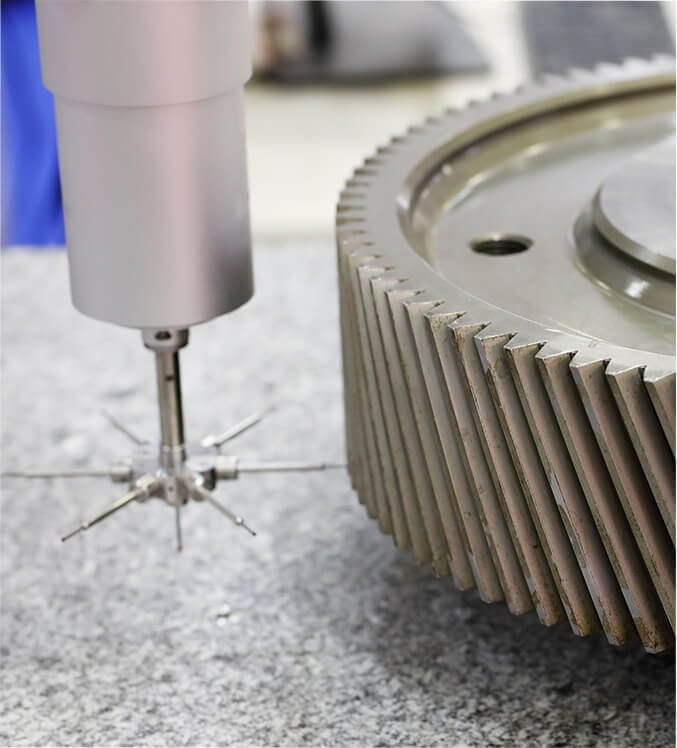

Hermle C 650 U 5-Axis Machining Center

The Hermle C 650 U is a high-precision 5-axis machining center with a 49.2” x 38.6” working area and a maximum pallet load capacity of 3,306 lbs. It features a modular design that can be configured for milling or mill-turn operations on large, complex parts. This machine also features 12 pallets, allowing repeatable jobs to be run with speed and precision.

Get

Get