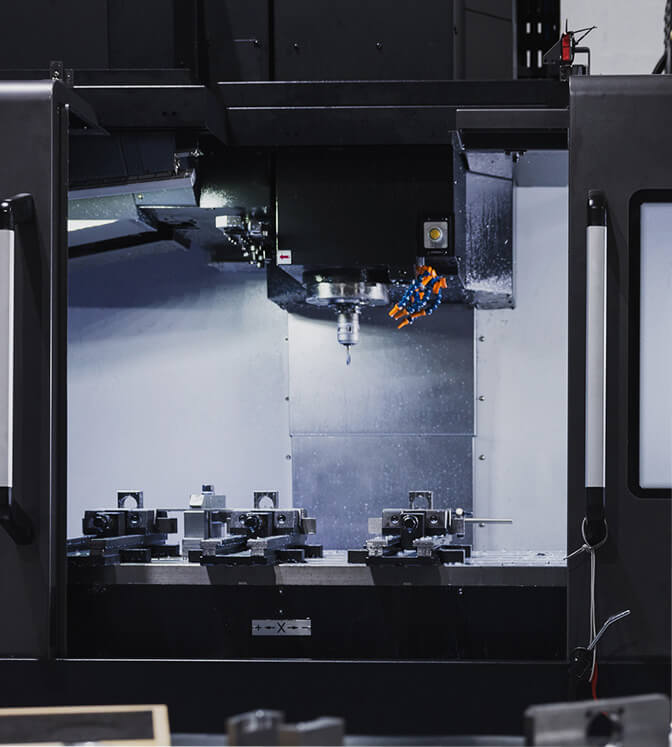

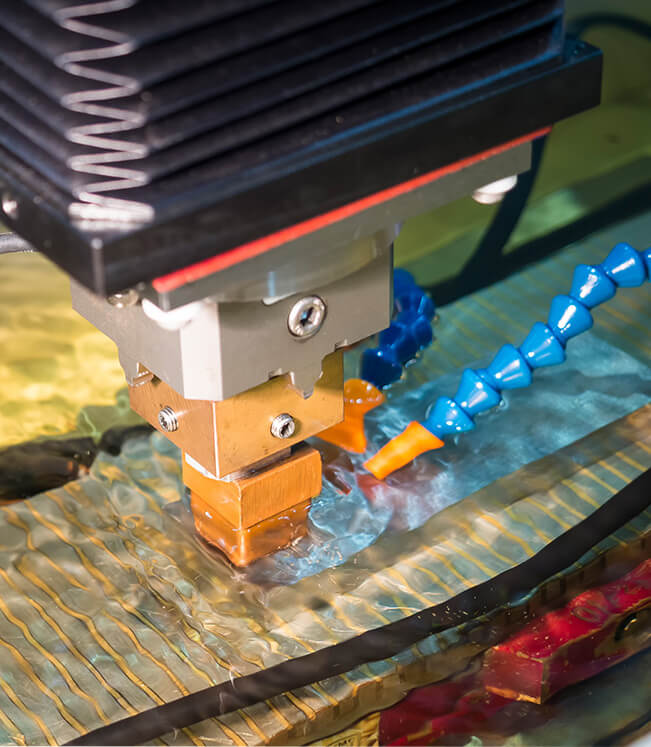

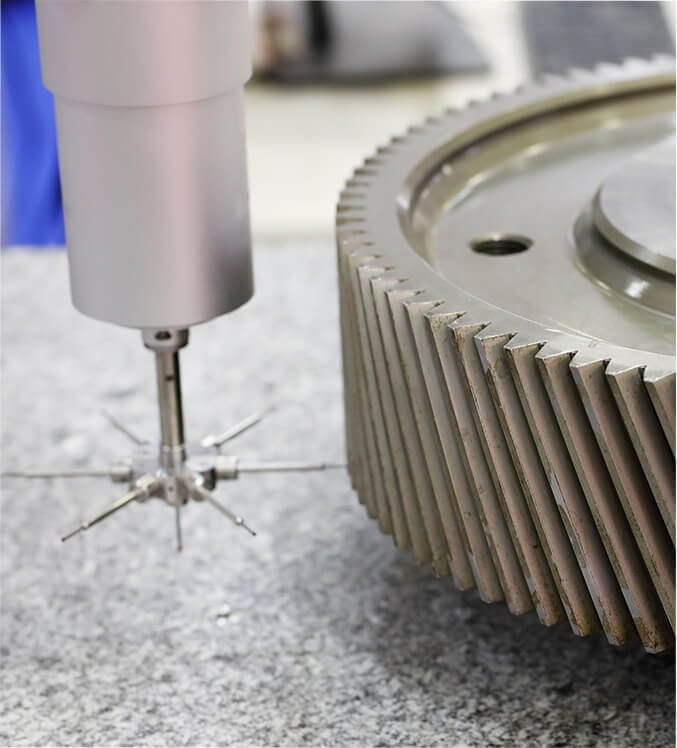

CNC Job Shop with 35 Overhead Cranes for Large CNC Jobs

RAM Tool, Inc. owns and employs over 35 Overhead Cranes for handling large CNC-machined parts. Our CNC job shop specializes in intricate large part manufacturing for the aerospace, military, automotive, and energy industries. Among our list of other CNC equipment includes Presses (Fitting Press, Radial Arm Drill Press), Sandblasting Cabinets, a Tempering Furnace, and Tool Storage Systems for efficiency. We purchase our machines and operate them entirely in-house inside our facility (based in Grafton, Wisconsin) allowing us to reduce lead time, provide manufacturer-direct pricing, and maintain total control over the entire machining process.

Get

Get