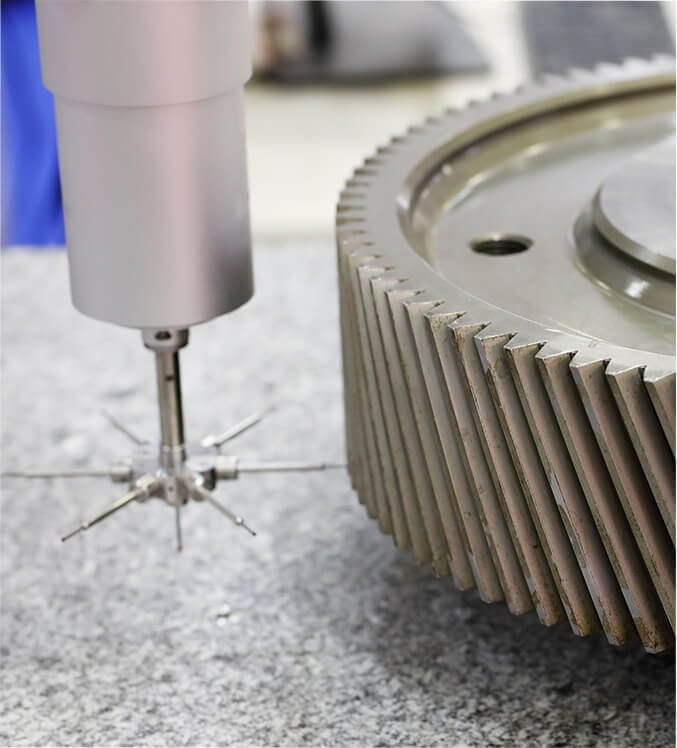

3D Laser Scanners

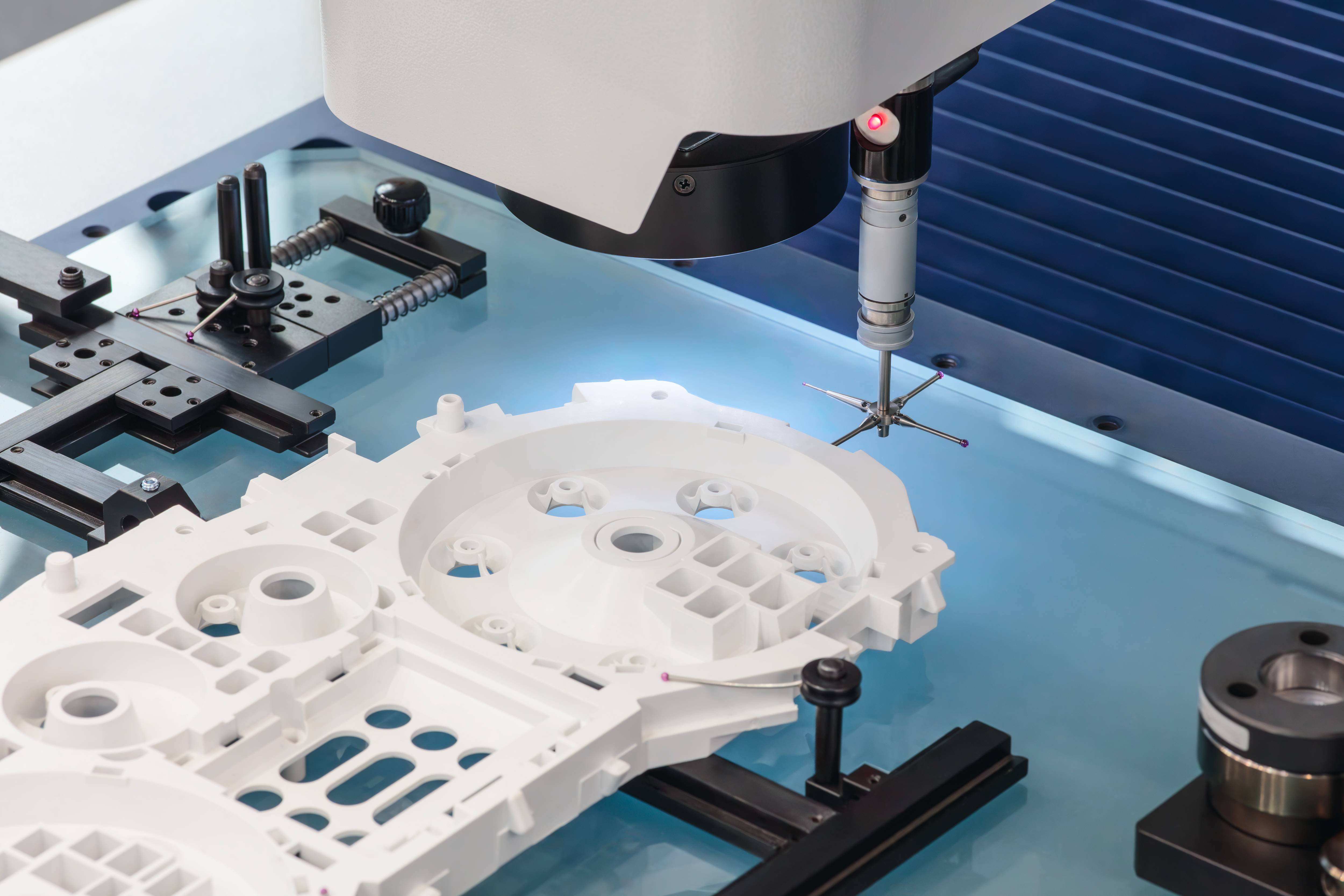

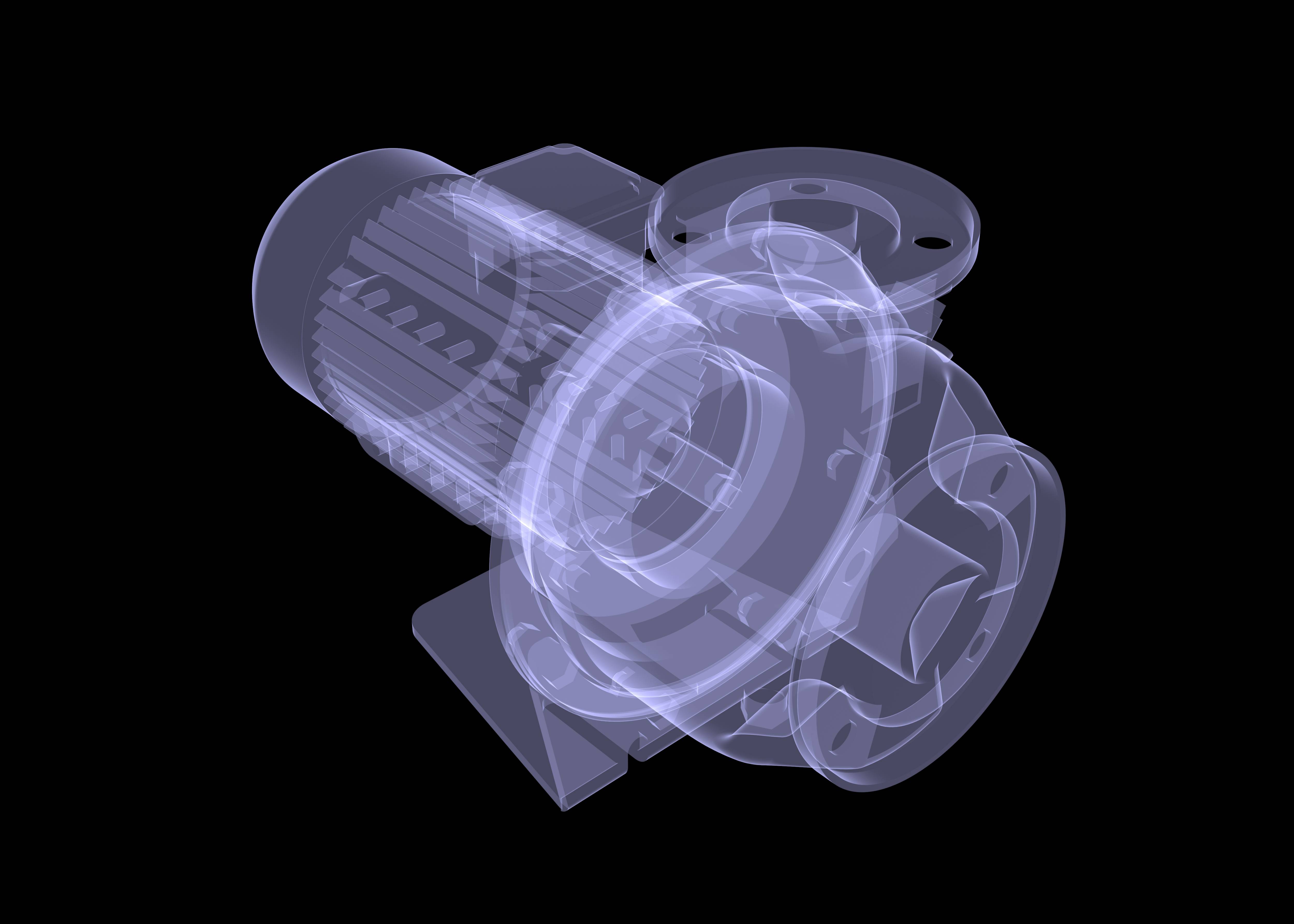

3D Laser Scanners are advanced tools used to digitize physical objects into accurate 3D models for CNC machining applications. They work by projecting laser lines onto a part’s surface and using sensors to capture the reflected light, creating a detailed point cloud that represents the object's geometry. This technology enables rapid reverse engineering of parts, quality control verification, and the creation of precise CAD files for CNC machining, significantly streamlining the process of replicating or modifying existing components.

RAM Tool is capable of rapid reverse engineering parts, verifying quality control, and creating of precise CAD files for CNC machining,to significantly streamlining the process of replicating or modifying existing components. We own one Hexagon AS1 Absolute Scanner in our facility which allows us to perform 3D laser scanning services for any CNC project.

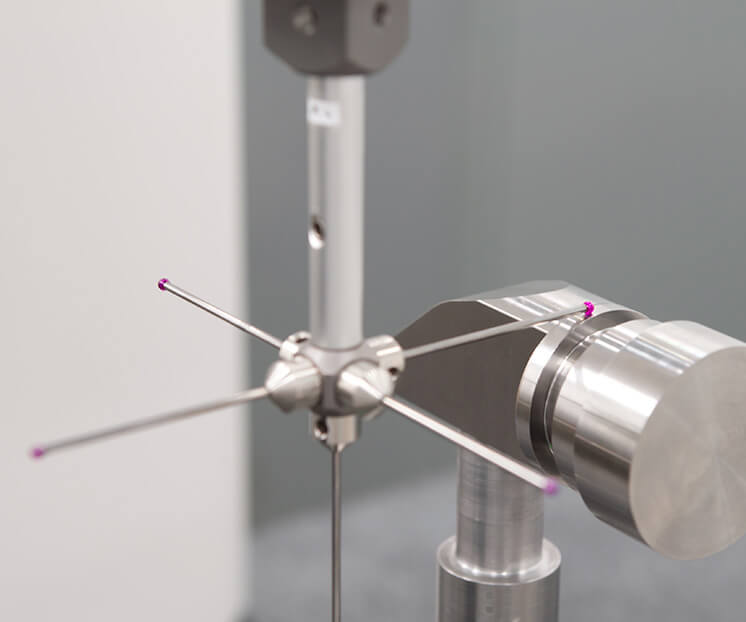

Hexagon AS1 Absolute Scanner

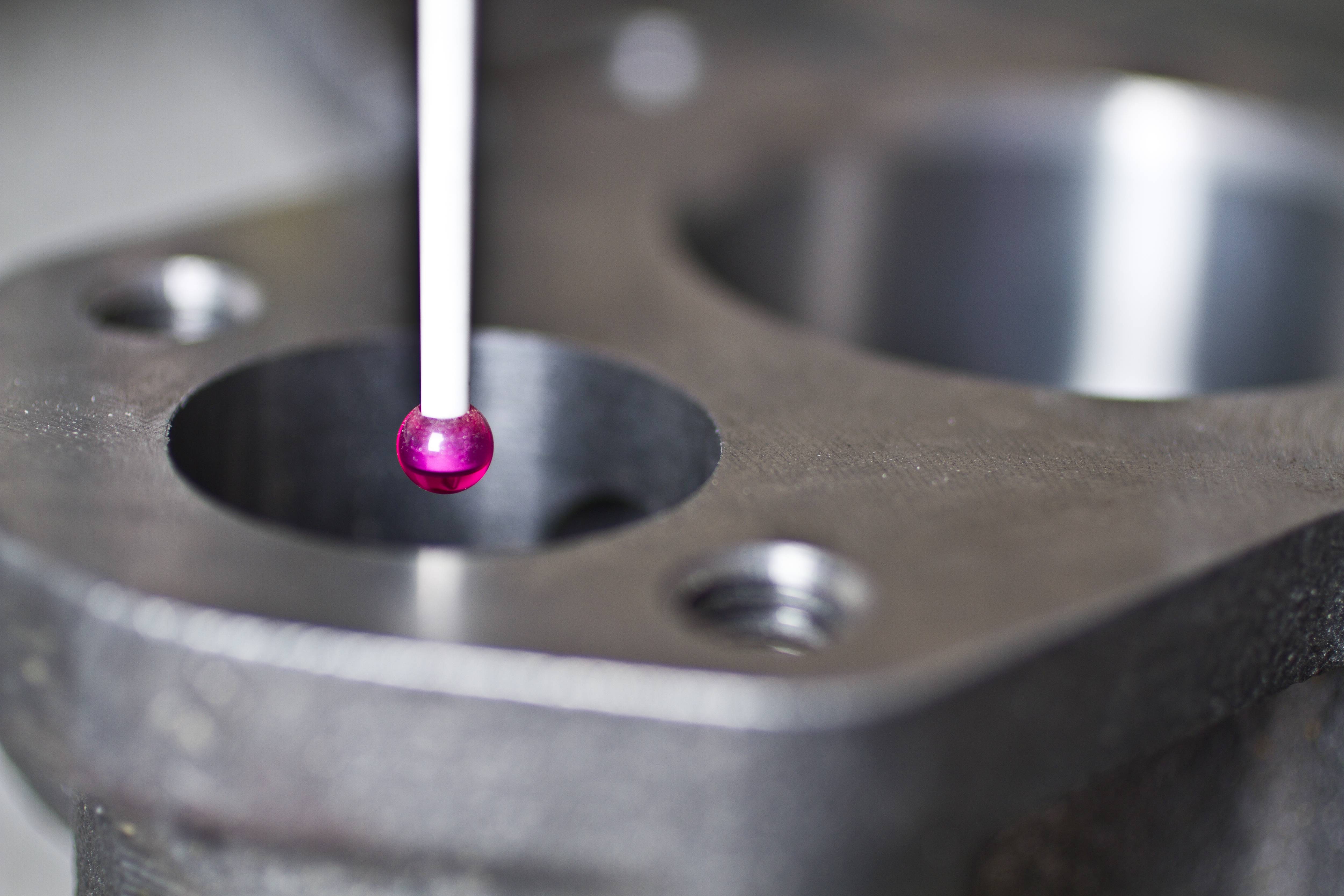

The Hexagon AS1 Absolute Scanner is a high-performance 3D laser scanner compatible with both Absolute Tracker and Absolute Arm measurement systems, offering cross-platform versatility without requiring realignment when switching. It features advanced SHINE technology for scanning various surface types, collects up to 1.2 million points per second at 300 lines per second, and provides measurement accuracy within 50 microns across a 60-meter diameter volume when used with an Absolute Tracker.

Get

Get