Precision CNC Machining Capabilities

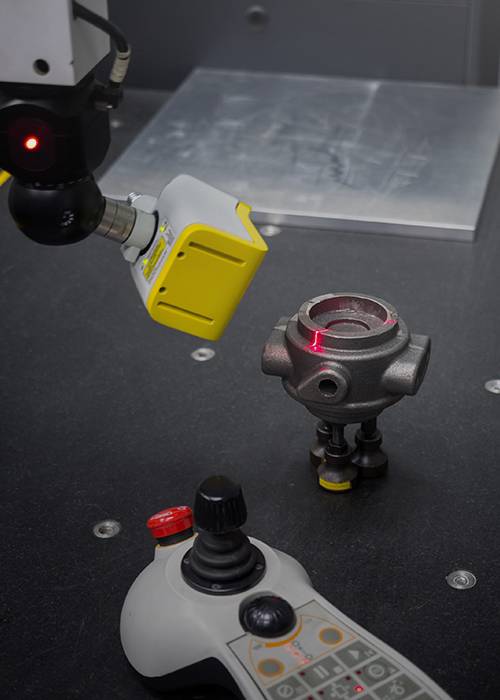

At our state-of-the-art 80,000 sq ft facility in Grafton, Wisconsin, we have a wide range of precision CNC machining capabilities to meet all of your project needs. Our machining capabilities include contract milling, custom inspection, die-cast dies, laser scanning, prototype tooling, and more. We've got the expertise and equipment to tackle any project, no matter how big or complex. Learn more about end-to-end CNC capabilities.

Get

Get