Benefits of Precision Machining to Medical Industries

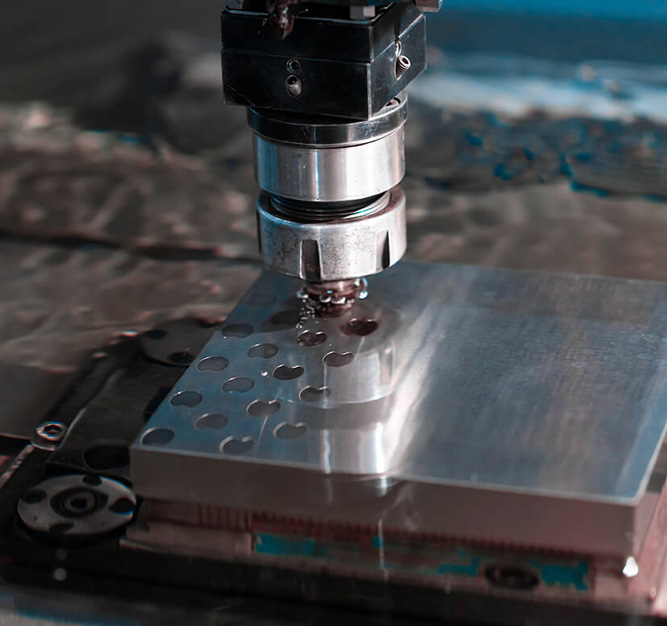

Precision CNC machining enhances medical manufacturing by producing high-quality components with extreme accuracy. Tight tolerances and repeatability guarantee implants, prosthetics and surgical tools meet strict specifications, improving patient safety and device reliability. By reducing human error through automated precision, CNC machining helps medical manufacturers maintain consistent quality across every component.

Efficiency is another key advantage. CNC automation accelerates production while reducing costs, allowing manufacturers to meet demand without compromising precision. Faster turnaround times support the rapid development of medical innovations, making CNC machining a cost-effective solution. Compared to other manufacturing methods, CNC machining minimizes waste and optimizes material use, improving overall production efficiency.

Versatility in material compatibility and ability to meet medical-grade standards further strengthen CNC machining’s value in the medical industry. CNC machining supports biocompatible metals and advanced polymers, enabling the production of durable, high-performance components. Precision, speed and adaptability make CNC machining a vital tool for advancing medical technology.

Get

Get

The CNC Advantage

The CNC Advantage