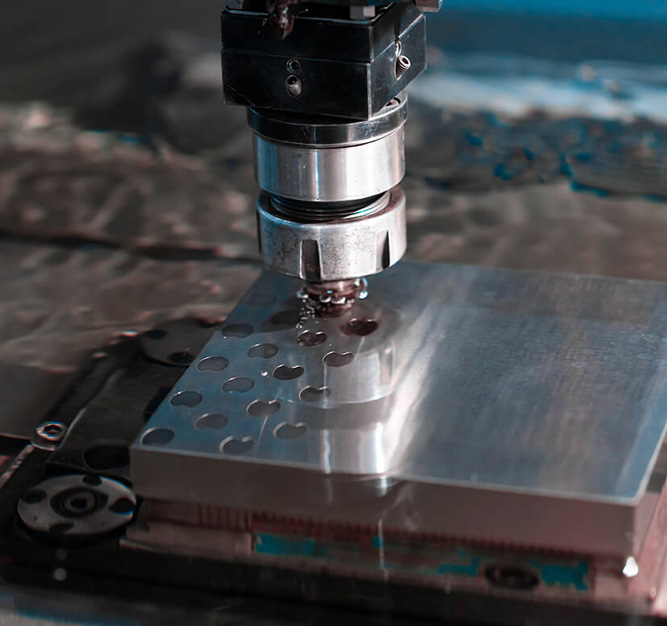

CNC Machining for the Medical Industry

RAM Tool provides medical CNC machining for the medical industry, manufacturing precision components for surgical instruments, implants and diagnostic equipment. Our technology-driven machining produces tight-tolerance parts supporting patient safety, performance and product innovation. From prototype development to high-volume production, RAM Tool delivers accurate, repeatable results through proven medical CNC machining services.

Contact RAM Tool today to discuss CNC machining for medical applications and your next medical manufacturing project.

Get

Get

The CNC Advantage

The CNC Advantage